Servo motors are widely used motors in the field of automation, and are usually used to drive more precise speed or position control components in projects. Designers of automation equipment often need to face various motor selection problems with different needs, and the motors provided by suppliers are also varied, with numerous parameters, which often confuse beginners. This article is only based on the author's actual work experience to do some Share, hope it can provide some help to those in need. 1. Application scenarios Control motors in the field of automation can be divided into servo motors, stepper motors, variable frequency motors, etc. Servo Motor drives are selected for components that require more precise speed or position control. The control method of inverter + variable frequency motor is a control method that changes the motor speed by changing the power frequency of the input motor. Generally only used for motor speed control. Servo motor compared to stepper motor: a) The servo motor uses closed-loop control, and the stepper motor is open-loop control; b) The servo motor uses the rotary encoder to measure the accuracy, and the stepper motor uses the step angle. The accuracy of the former on the ordinary product level can reach a hundred times the order of magnitude of the latter; c) The control method is similar (pulse or direction signal).

2. Power supply Servo motors can be divided into Ac Servo motors and DC servo motors from the power supply. Both are still better choices. For general automation equipment, Party A will provide standard 380V industrial power supply or 220V power supply. At this time, the servo motor corresponding to the power supply can be selected, eliminating the need to convert the power supply type. However, there are some devices, such as shuttle boards in three-dimensional warehouses, AGV trolleys, etc., due to their mobile nature, most of them use their own DC power supply, so DC servo motors are generally used. 3. Brake According to the design of the action mechanism, consider whether it will cause the reversal trend of the motor in a power failure state or a static state. If there is a reverse trend, you need to choose a servo motor with a holding brake. 4. Selection calculation Before the selection calculation, the first thing to determine is the position and speed requirements of the end of the mechanism, and then determine the transmission mechanism. At this point, the servo system and the corresponding reducer can be selected. In the selection process, the following parameters are mainly considered: 4.1 Power and speed Calculate the required power and speed of the motor based on the structural form and the speed and acceleration requirements of the final load. It is worth noting that in general, the reduction ratio of the reducer needs to be selected in combination with the speed of the selected motor. In the actual selection process, for example, the load moves horizontally, because of the uncertainty of the friction coefficient and wind load coefficient of each transmission mechanism, the formula P=T*N/9549 often cannot be clearly calculated (the magnitude of the torque cannot be accurately calculated). In the practice process, it is also found that the maximum power required by the use of the servo motor is often the acceleration and deceleration stage. Therefore, T=F*R=m*a*R can quantitatively calculate the required power of the motor and the reduction ratio of the reducer (m: load mass; a: load acceleration; R: load rotation radius). There are a few things to note: a) The power margin coefficient of the motor; b) Consider the transmission efficiency of the mechanism; c) Whether the input and output torque of the reducer meets the standard and has a certain safety factor; d) Whether there is a possibility of increasing the speed in the later stage. It is worth mentioning that in traditional industries, such as cranes and other industries, ordinary induction motors are used to drive, and there is no clear requirement for acceleration, and the calculation process uses empirical formulas. Note: When the load is running vertically, pay attention to the calculation of the gravitational acceleration.

4.2 Inertia matching To achieve high-precision control of the load, it is necessary to consider whether the inertia of the motor and the system match. For the question of why inertia matching is required, there is no unified statement on the Internet. Personal understanding is limited, so I won't explain it here. Friends who are interested can test it by themselves and let them know. The principle of inertia matching is: considering that the inertia of the system is converted to the motor shaft, and the ratio of inertia to the motor is not greater than 10 (Siemens); the smaller the ratio, the better the control stability, but a larger motor is required, and the cost performance is lower. If you don't understand the specific calculation method, please make up the "Theoretical Mechanics" of the university by yourself. 4.3 Accuracy requirements Calculate whether the control accuracy of the motor can meet the requirements of the load after the change of the reducer and transmission mechanism. The reducer or some transmission mechanisms have a certain return clearance, which needs to be considered. 4.4 Control Matching This aspect is mainly to communicate with the electrical designer to confirm, such as whether the communication mode of the Servo Controller matches the PLC, the type of the encoder and whether the data needs to be exported. It is worth mentioning that, to do automated design, we must learn to borrow external forces. Especially for non-standard automation, it is often overwhelmed by the selection and calculation of too many equipment, and it is normal to work overtime to become a dog. As a servo motor manufacturer, we provide technical support. As long as you provide us with parameters such as load, speed, acceleration, etc., we have a set of our own software to automatically help you calculate and select the appropriate servo motor, which is very convenient.

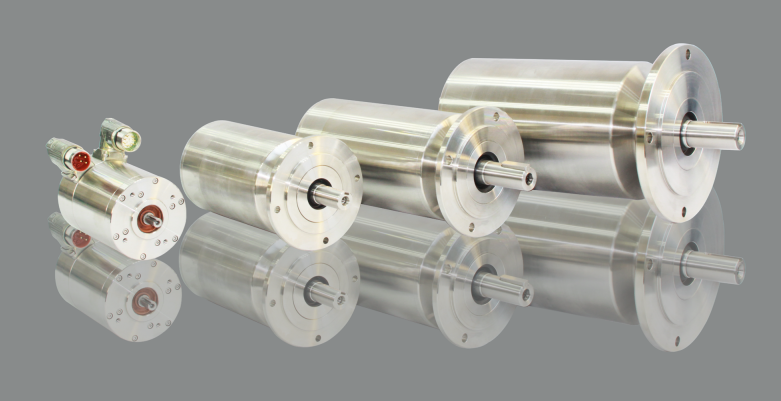

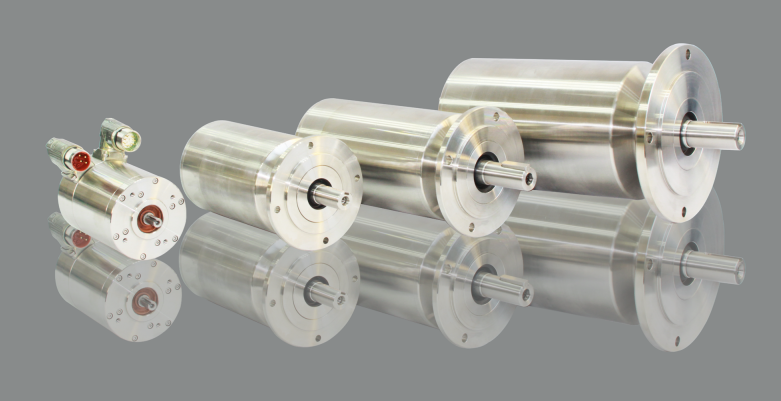

![]() June 18, 2022

June 18, 2022